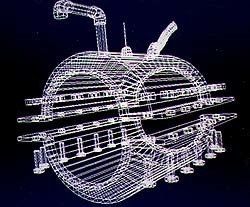

ICE-O-LATOR© Technology

In pipeline maintenance, hydrostatic testing and leak detection, it is often necessary to isolate valves and sections of pipe. A safe, reliable and economical way to accomplish this is with the use of our ICE-O-LATOR© System.

Read more

Introducing liquid nitrogen in to the ICE-O-Lator rapidly freezes the contents of the pipe to form a plug, or line stop which makes it possible to isolate valves, vessels, pumps, equipment and other facilities for repair, modifications or hydrostatic testing. The ICE-O-LATOR© System utilizes precision monitoring equipment to develop a reliable freeze plug for single or multiple applications, regardless of the pressures exerted.

We developed and patented this unique method of freezing a plug within a pipe. This process is offered exclusively by Freeze Technology International, Ltd and our subsidiary companies.

We offer turnkey solution for the following applications:

We provide temporary pipe plugging services to the following industries:

- Midstream Pipeline Companies

- Refineries

- Hospitals

- Commercial Buildings

- Chemical Plants

- Hotels

- Water and Waste treatment plants

- Paper mills

- Breweries

- Nuclear and Fossil fuel power plants

- Ships

- Isolation for Hydrostatic testing

- Leak locating

- Isolation for repairs or modification

The Ice-O-Lator® System has proven successful on a variety of pipe including:

- Stainless Steel

- Brass

- Carbon Steel

- Copper

- Cast Iron

- Aluminum

- Fiberglass

- Horizontal

- Transite

- Vertical

- Out of Round

- Internally or Externally Coated

- Cement Lined

Our highly trained, nuclear qualified technicians are available 24 hours a day, so whether your day is beginning or ending, you can depend on the ICE-O-LATOR® System to be there when you need it.

ICE-O-LATOR® equipment is installed exactly where the plug is needed.

Each of our Service Centers maintains equipment for pipe from 1/2″ to 42″ diameter, and our own liquid nitrogen tanks and tankers.